-

-

Forklift handling mobile robot

Forklift handling mobile robot Reach mobile robots

Reach mobile robots SLIM

SLIM Jacking robot

Jacking robot Cooperation robot

Cooperation robot Roller mobile robot

Roller mobile robot Towing mobile robot

Towing mobile robot Platform handling robot

Platform handling robot Heavy-load robot

Heavy-load robot Outdoor loading mobile robot

Outdoor loading mobile robot Pick robot

Pick robot Parking robot

Parking robot Agricultural robot

Agricultural robot Driverless Road Roller robot

Driverless Road Roller robot Driverless Sanitation vehicle

Driverless Sanitation vehicle

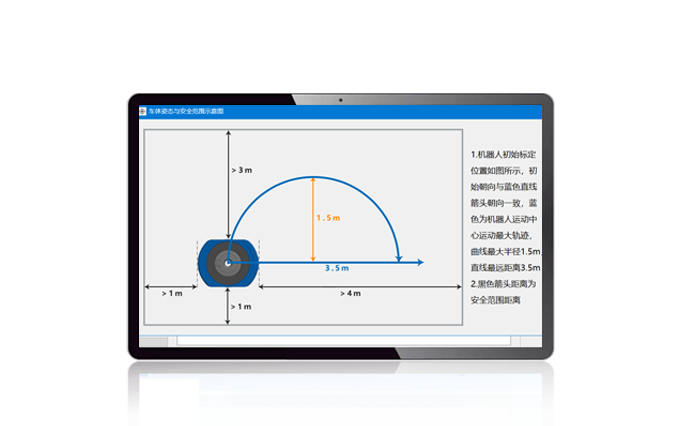

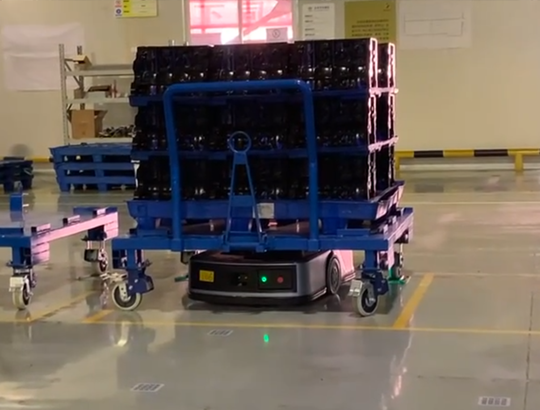

The Jacking AMR achieves material transportation by infiltrating the bottom of the material rack and utilizing the lifting mechanism to raise the rack. It can support various carriers such as shelves, material carts, and cage cars, and is commonly used for the transfer of material racks and carts. This product effectively reduces labor costs and alleviates manual labor intensity.

As one of the fastest growing types of mobile robots (AMR/AGV) in recent years, AMR has been favored by intelligent factories due to its small size and low vehicle height.With increasing market demand and more diverse applications, AMR and other types of mobile robots (AGV/AMR) are gradually moving towards standardization. The design of AMR vehicles is becoming more professional and compact, with standardized functions, which also places higher demands on the core controllers of AMR.

Jacking AMR with KC controller

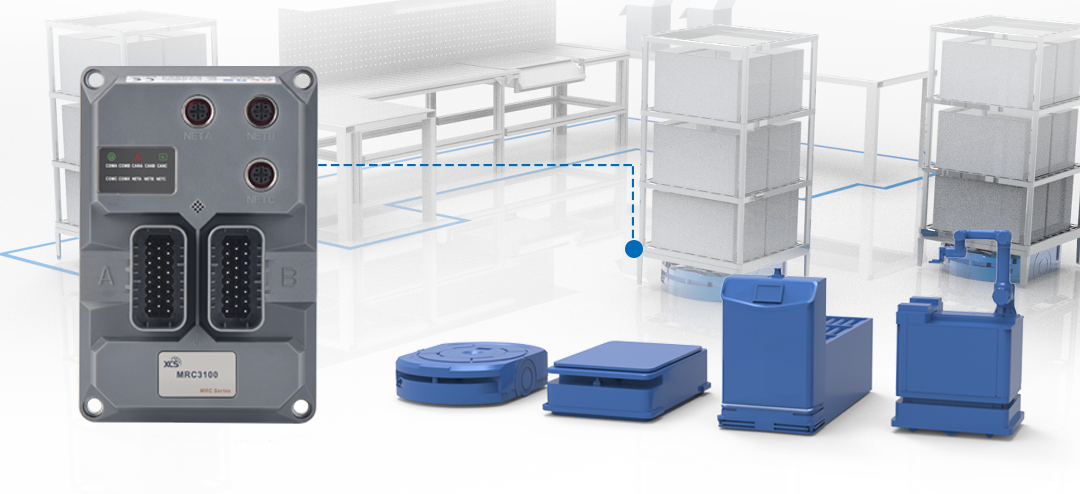

To promote the standardization and refinement of AMR vehicle development, KC officially launch a new product in the field of mobile robot segmentation - the AMR mobile robot controller in 2023.

The birth of the AMR mobile robot controller is a powerful tool for the development of the lifting cart AMR. As the smallest controller in history, it can perfectly fit the small-volume design of the lifting cart AMR.

KC solution:

What is the advantage and cor technology of the AMR controller?

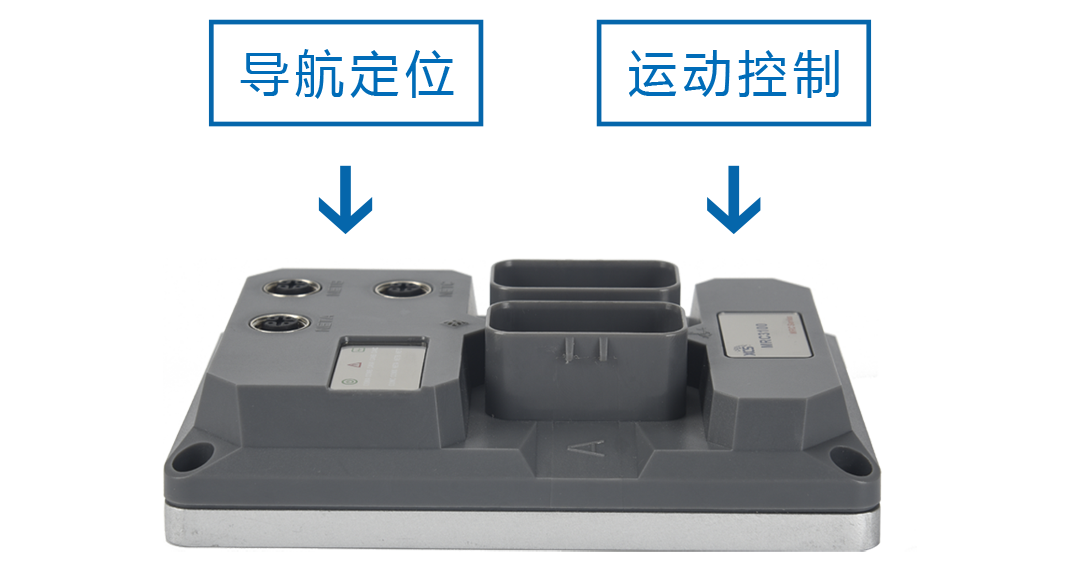

AMR Mobile Robot Controller Core Technology:

High-reliability technical-level ARM built-in hardware platform

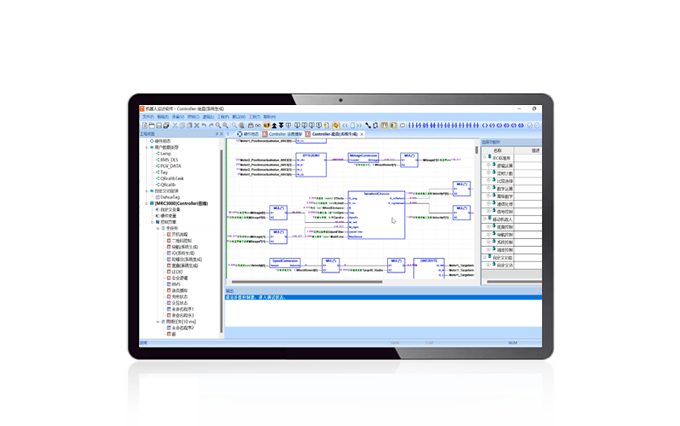

4-core processor, integrated with fully autonomous programmable kernel and graphical low-code application development environment compiler.

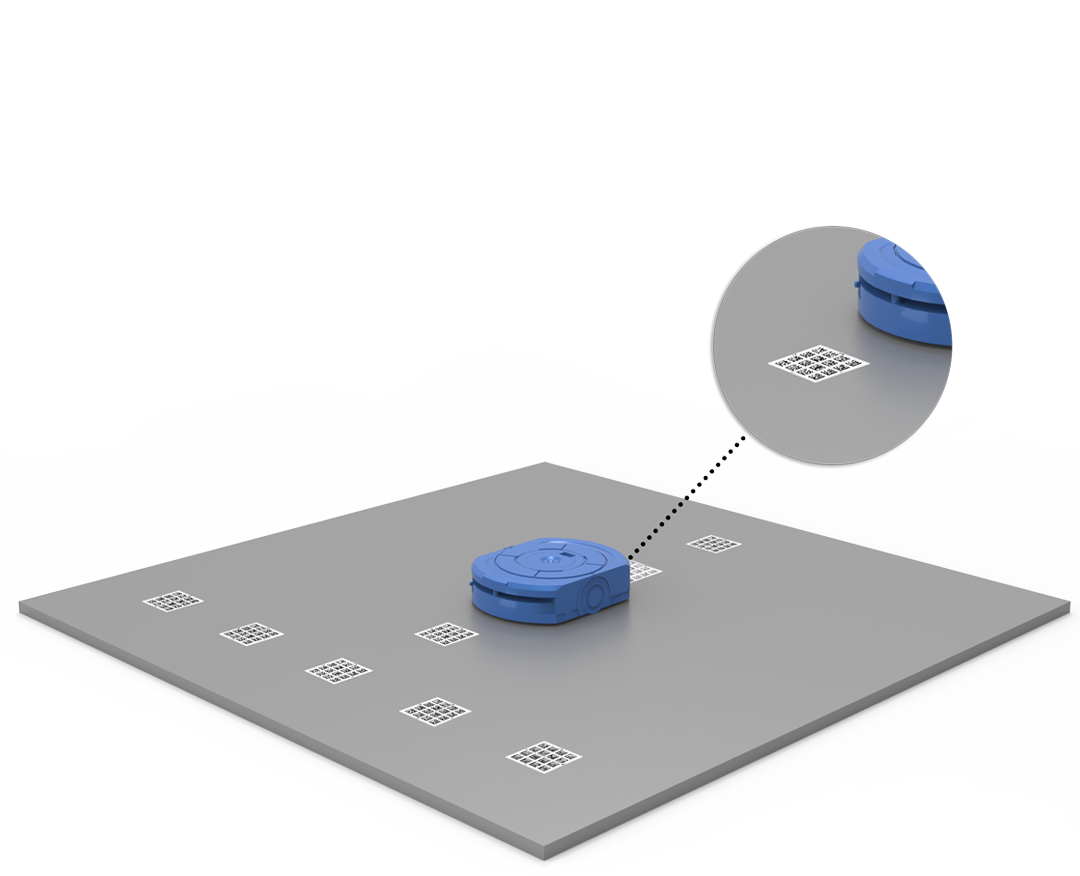

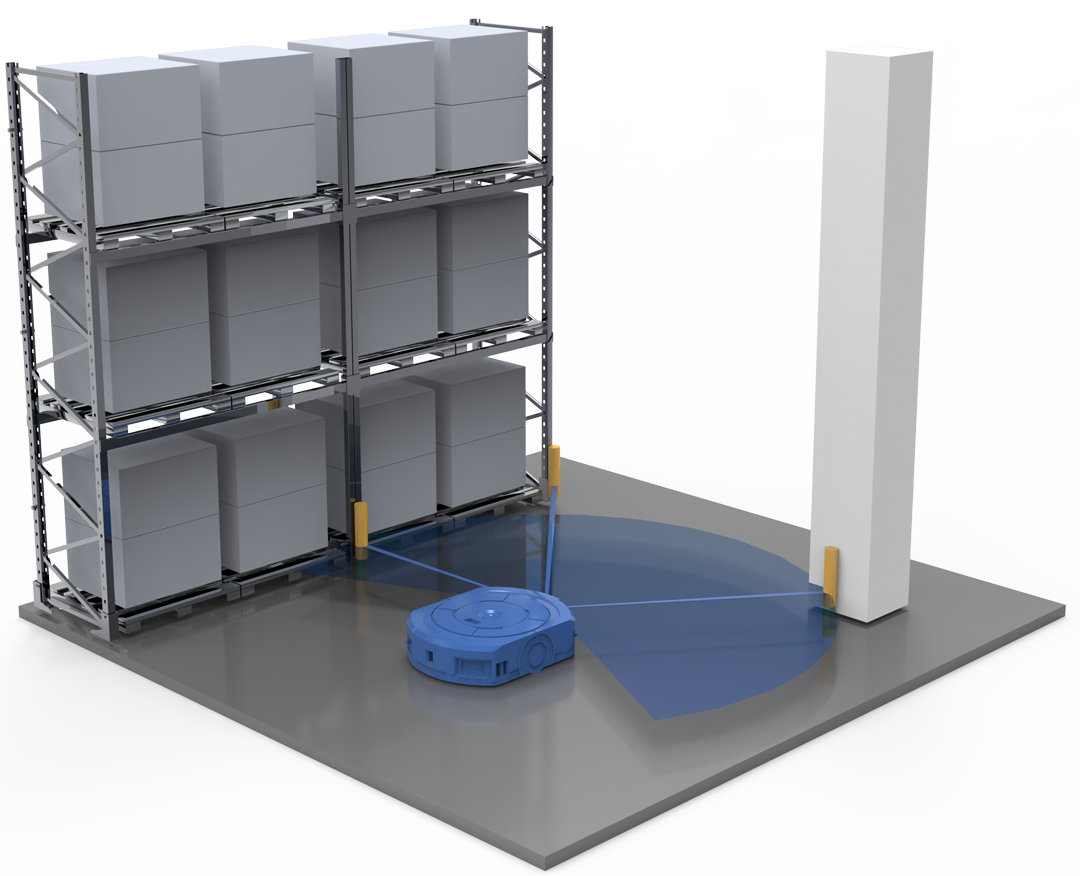

Built-in navigation algorithms

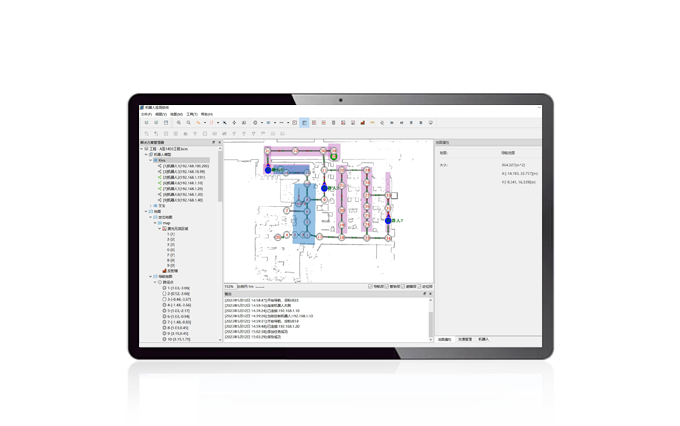

Support laser navigation and barcode navigation

Built-in motion control algorithms

Support two-wheel drive differential,four-wheel drive differential

Behind the high-quality and cost-effective AMR mobile robot controller, there is the accumulation of years of experience that KC has gained in various AMR solutions. By choosing KC's AMR mobile robot controller, users can quickly and flexibly adapt to the various navigation sensors, drive modules, safety modules, and other functional modules required for a lifting cart AMR. At the same time, KC's complete supply chain system can quickly complete vehicle configuration design and selection list according to customer needs.