Plans and Cases

Fork type

Fork mobile robots are suitable for loading, unloading, stacking, and transporting pallet goods of different heights. It can complete a series of actions, such as lifting, carrying, and transporting palletized goods without additional special carriers, to realize less labour force and automatic logistics on the factory.

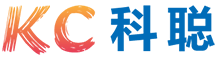

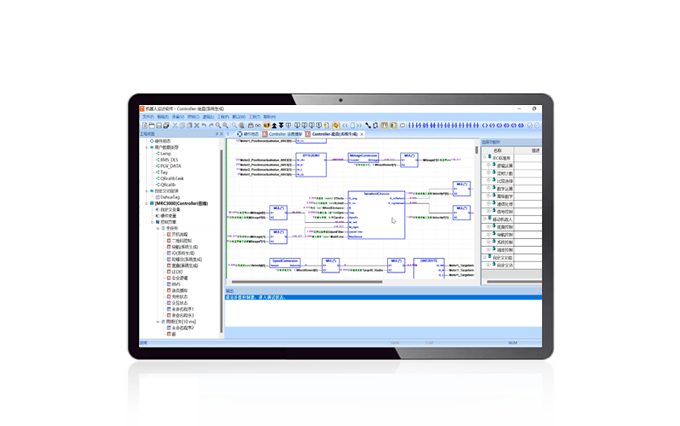

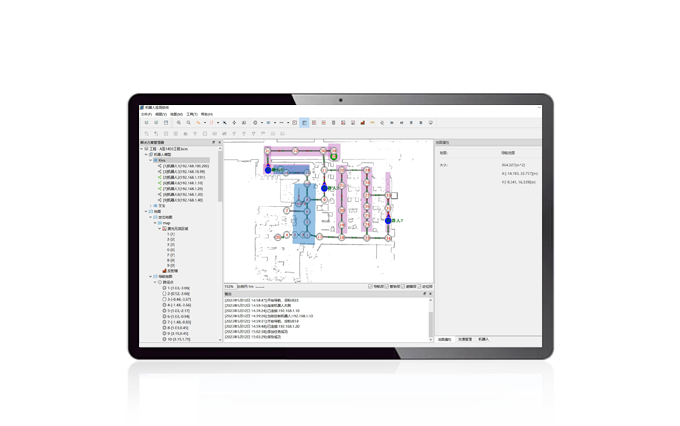

The overall solution of fork-type handling mobile robot is mainly divided into nine modules according to the whole vehicle function of the mobile robot, such as control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and optional functions.

The overall solution of fork-type handling mobile robot is mainly divided into nine modules according to the whole vehicle function of the mobile robot, such as control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and optional functions.

More

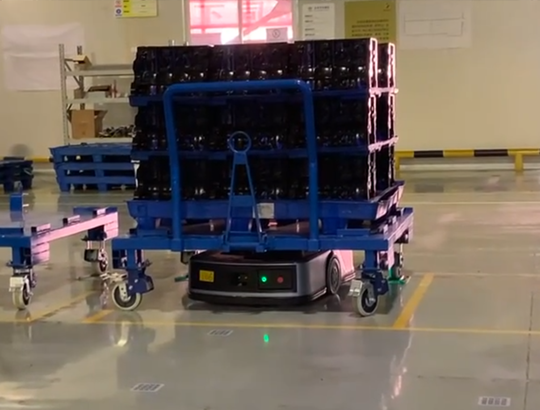

Jacking type

The Jacking-type mobile robot carries pallets, shelves, and other carriers by jacking, lifts the transported materials and shelves, transports them quickly to the designated position, and completes the shelf deployment, sorting, integration, and other work in the storage plant workshop. It automatically connects with the transplantation mechanism, lifting and lowering mechanism, and the equipment of the standing library, to achieve unmanned operation.

The overall solution of jacking and transporting type, according to the whole vehicle function of mobile robot, is mainly divided into the control system, navigation, and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, optional additional functions, such as the composition of the nine major unit modules.

The overall solution of jacking and transporting type, according to the whole vehicle function of mobile robot, is mainly divided into the control system, navigation, and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, optional additional functions, such as the composition of the nine major unit modules.

More

Cooperation type

Cooperation mobile robots in the unmanned handling chassis based on the addition of a robotic arm can complete the material in the mobile robot and equipment between the machine loading and unloading work, but also through the vision sensor on the arm of the material all-round detection.

The cooperation mobile robot's overall solution, according to the mobile robot vehicle function, is mainly divided into the control system, navigation sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and optional functions, such as nine unit module composition.

The cooperation mobile robot's overall solution, according to the mobile robot vehicle function, is mainly divided into the control system, navigation sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and optional functions, such as nine unit module composition.

More

Roller type

The roller mobile robot is to add a roller mechanism based on unmanned handling chassis to form a production line docking robot, which can achieve a seamless connection between workshop and warehouse, production line and production line, and production equipment and production equipment.

The overall solution of the roller mobile robot is mainly divided into nine unit modules, such as control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and add functions, etc., according to the function of the whole vehicle of the mobile robot.

The overall solution of the roller mobile robot is mainly divided into nine unit modules, such as control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, and add functions, etc., according to the function of the whole vehicle of the mobile robot.

More

Pick type

Pick robot is an intelligent logistics handling equipment, which can realize intelligent picking, accessing and handling of multiple pallet. Without the use of any track, it can move forward, backward, turn, with autonomous navigation, active obstacle avoidance and automatic charging and other functions.

According to the whole vehicle function of the mobile robot, the overall solution of the bin-type mobile robot is mainly divided into control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, add functions and other nine unit modules.

According to the whole vehicle function of the mobile robot, the overall solution of the bin-type mobile robot is mainly divided into control system, navigation and sensing, chassis drive, actuator, safety detection, interaction module, communication module, power supply unit, add functions and other nine unit modules.

More

Towing type

The towing mobile robot adopts a tail hook to tow material trolleys, which can tow several material trolleys at the same time to achieve efficient handling and improve transport efficiency. It is suitable for the transfer of material trolleys in the production workshop and the delivery of material trolleys to the workstations.

The overall solution of a traction mobile robot is mainly divided into control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other units and modules according to the function of the whole vehicle of the mobile robot.

The overall solution of a traction mobile robot is mainly divided into control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other units and modules according to the function of the whole vehicle of the mobile robot.

More

Heavy-load type

The heavy-duty mobile robot is a kind of intelligent vehicle powered by a battery or an internal combustion engine, equipped with high-power motors, gearboxes, and universal drive wheels to achieve flexible operation, with speed adjustment, lift compensation, vehicle braking, omnidirectional steering, free path planning, automatic guidance, online fast charging, multi-vehicle grouping linkage and other functions, and at the same time, can be centrally managed by the centralized dispatching.

The overall solution for heavy-duty mobile robots is mainly divided into the control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other modules according to the function of the whole vehicle of the mobile robot.

The overall solution for heavy-duty mobile robots is mainly divided into the control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other modules according to the function of the whole vehicle of the mobile robot.

More

Platform handling type

The platform handling mobile robot transports the target goods (materials and carriers) to the designated place using backpacking to achieve unmanned operation in the factory and production line.

The overall solution of a platform handling mobile robot is mainly divided into the control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add function, and other unit modules according to the whole vehicle function of the mobile robot.

The overall solution of a platform handling mobile robot is mainly divided into the control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add function, and other unit modules according to the whole vehicle function of the mobile robot.

More

Parking type

The parking robot will automatically and precisely carry the car driven into the parking platform by the user to the parking space, and then automatically carry the car to the user's pick-up space when picking up the car. The parking robot not only saves the parking space, but also shortens the vehicle access time, providing a comfortable and convenient parking service.

The overall solution of parking mobile robot is mainly divided into unit modules consisting of control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, and optional functions according to the whole vehicle function of the mobile robot.

The overall solution of parking mobile robot is mainly divided into unit modules consisting of control system, navigation and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, and optional functions according to the whole vehicle function of the mobile robot.

More

Outdoor type

Outdoor mobile robots carry out handling outdoors, generally using 4W4D chassis.

The overall solution of outdoor mobile robots is mainly divided into the control system, navigation, and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other units and modules according to the function of the whole vehicle of the mobile robot.

The overall solution of outdoor mobile robots is mainly divided into the control system, navigation, and sensing, chassis drive, safety detection, interaction module, communication module, power supply unit, add functions, and other units and modules according to the function of the whole vehicle of the mobile robot.

More

Industry applications

Warehouse Logistics

Unmanned logistics warehousing, initially originated from the need to improve the efficiency of the logistics system. With the emergence of online shopping, the logistics industry has gradually become a major driver of China's economy and offered a large number of job opportunities. Since the logistics industry, where someone can deliver goods, has entered a highly competitive period, how to improve logistics efficiency, reduce personnel costs, and make products reach consumers faster has become the focus of attention of major logistics companies.

Nowadays, mobile robots are widely used, warehousing logistics refers to internal warehousing in general, generally referring to the production line side of the warehouse and centralized storage warehouses.

Nowadays, mobile robots are widely used, warehousing logistics refers to internal warehousing in general, generally referring to the production line side of the warehouse and centralized storage warehouses.

More

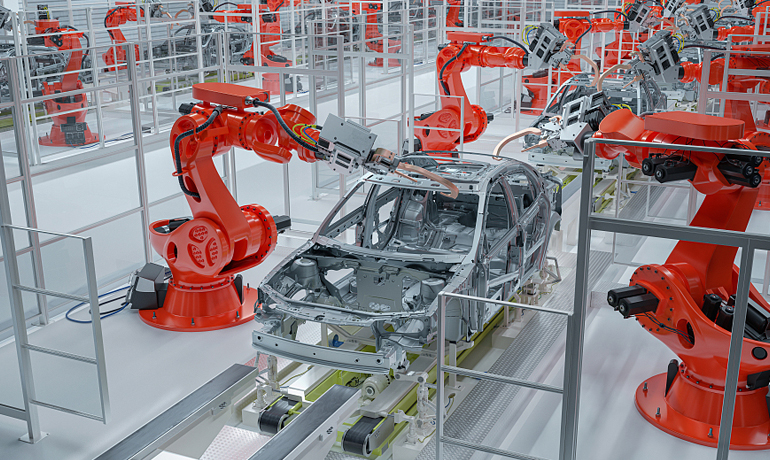

Automotive

Automotive is one of the world's largest and most important industries with the highest output value and occupies a considerable proportion of the global manufacturing industry. With the upgrading of consumption and diversification of market demand, the automotive industry needs more efficient and flexible production methods to meet the market demand under fierce competition.

Along with the continuous upgrading and innovation of the automotive industry, mobile robots (AGV/AMR) play a more and more important role in the automotive manufacturing production line with their unique technical advantages of high efficiency, flexibility, and safety.

Along with the continuous upgrading and innovation of the automotive industry, mobile robots (AGV/AMR) play a more and more important role in the automotive manufacturing production line with their unique technical advantages of high efficiency, flexibility, and safety.

More

Semi-conductor

The semiconductor industry is a modern high-tech industry and an emerging strategic industry, which is one of the foundations of modern information technology, electronic technology, communication technology, information technology, and other industries. China's government has formulated the China Integrated Circuit Industry Development Plan and the China Artificial Intelligence Development Plan, which clearly promote the development of semiconductor and artificial intelligence and other industries, providing more policy support and development opportunities for the semiconductor industry.

In this industry, time is money while productivity is key. Therefore, the application of mobile robots (AGV/AMR) is particularly important in the semiconductor industry.

In this industry, time is money while productivity is key. Therefore, the application of mobile robots (AGV/AMR) is particularly important in the semiconductor industry.

More

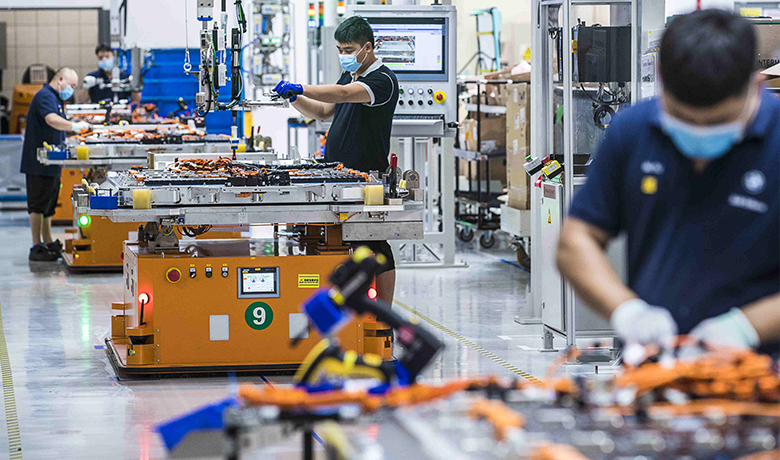

Lithium industry

With the feature of mature and advanced, lithium-ion batteries are widely used because of their lightweight and high storage capacity. China, as the world's largest producer and consumer of lithium batteries, is also the world's largest electric vehicle market. With the goal of "carbon neutrality", lithium-ion battery technology can provide carbon neutrality for electric vehicles, energy storage systems, smart grids, and other important applications, and also reduce the country's carbon emissions and energy consumption.

The mutual integration of the lithium industry and intelligent manufacturing technology can enhance the ability to resist the risk of market competition, triggering huge investment opportunities and market demand, promoting the transformation and upgrading of the lithium industry, and injecting new impetus for the sustainable development of the new energy industry.

The mutual integration of the lithium industry and intelligent manufacturing technology can enhance the ability to resist the risk of market competition, triggering huge investment opportunities and market demand, promoting the transformation and upgrading of the lithium industry, and injecting new impetus for the sustainable development of the new energy industry.

More

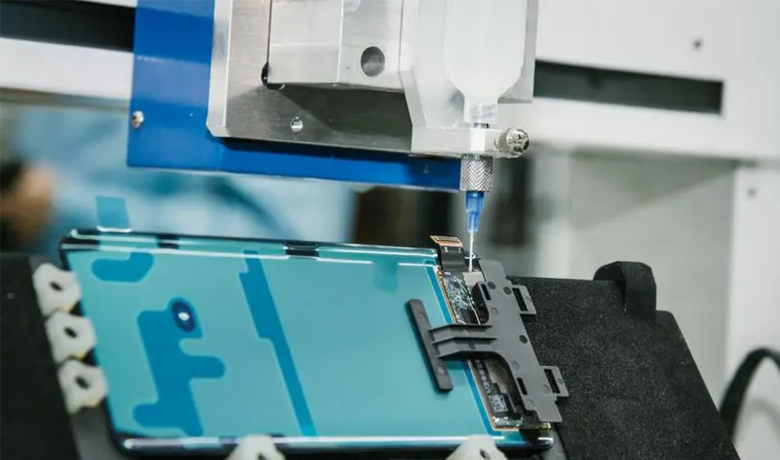

Electronics

China is a large Electronic manufacturing country and occupies 70% of the global production capacity, which means Electronic product processing and assembly factories are overwhelmingly in China. Nowadays, the 3C manufacturing industry is undergoing automation upgrading, mobile robots, robotic arms, and other industrial robots have been applied on a large scale.

More