Mobile robot industry applications - lithium industry

As a mature and advanced battery, lithium-ion batteries are widely used because of their light weight and high storage capacity. China, as the world's largest producer and consumer of lithium batteries, is also the world's largest electric vehicle market. With the goal of "carbon neutrality", lithium-ion battery technology can provide carbon neutrality for electric vehicles, energy storage systems, smart grids, and other important applications, and also reduce the country's carbon emissions and energy consumption.

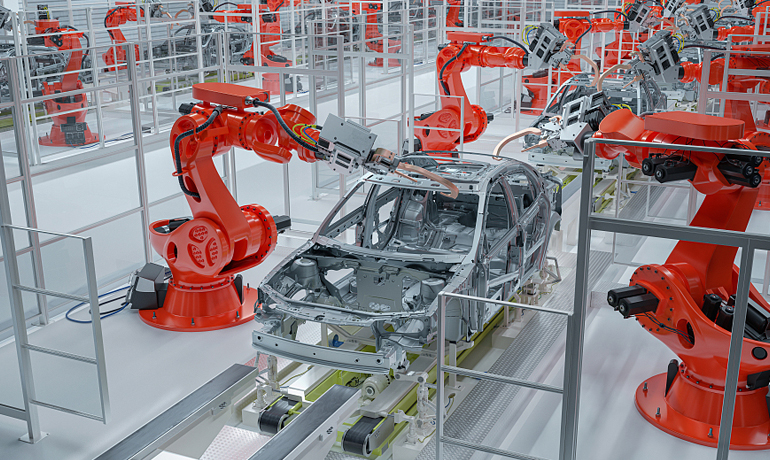

The mutual integration of lithium industry and intelligent manufacturing technology can enhance the ability to resist the risk of market competition, triggering huge investment opportunities and market demand, promoting the transformation and upgrading of lithium industry, and injecting a new impetus for realizing the sustainable development of new energy industry.

Difficulties:

①High quality consistency requirements for the manufacturing process

②High environmental cleanliness requirements of the production plant

③Higher requirements for the precision and stability of process control

④fast respond to clients needs

....

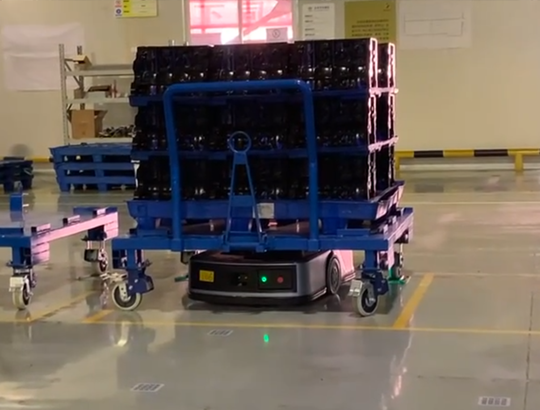

AGV/AMR application

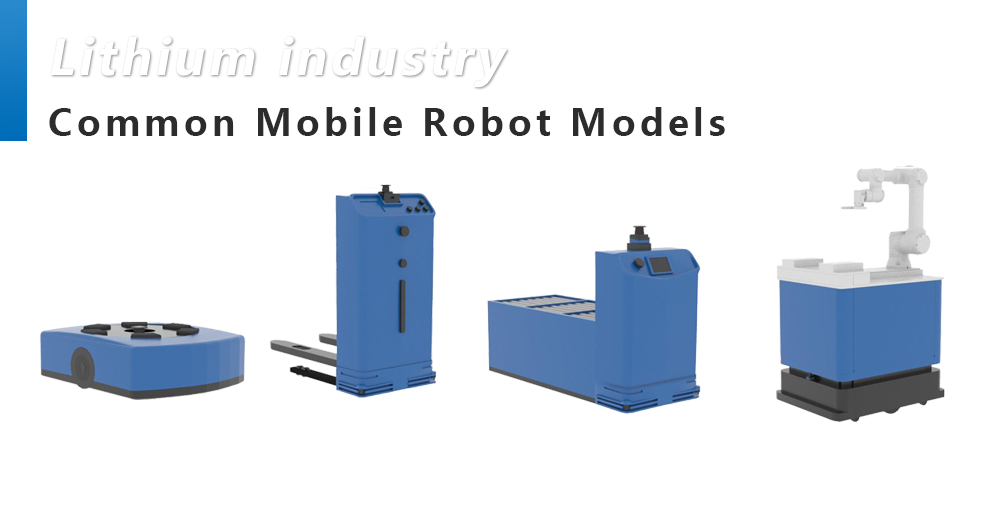

Mobile robots as a new type of productivity, is gradually applied to the lithium industry to improve production efficiency, reduce production costs, production safety.

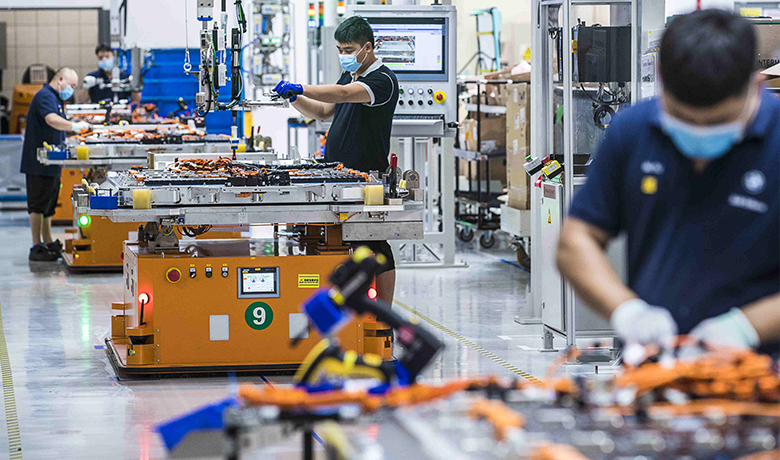

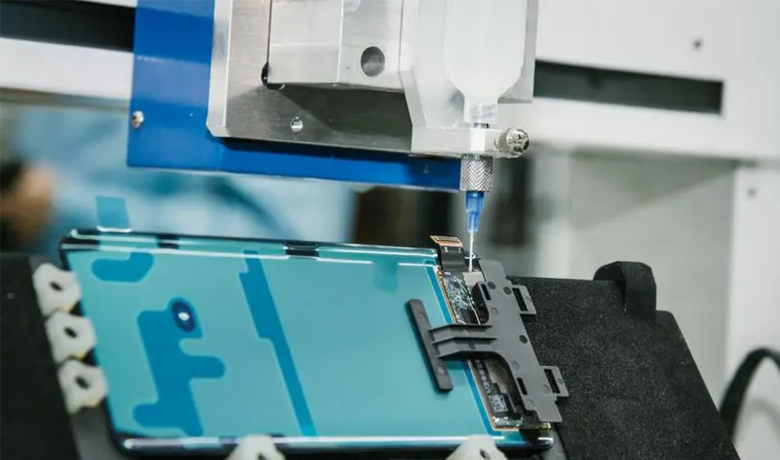

In the front-end process: The front-end process is very important, accounting for about 40% or more of the entire battery production process. Incoming material unpacking, handling, coil changing and line-side transfer can all be done with mobile robots (AGV/AMR) to replace traditional manual labour.

In the mid-end process: mobile robots are mainly used for loading and unloading in the winding/stacking process. The use of mobile robots (AGV/AMR) for automatic handling and docking can not only meet the requirements of accurate docking, but also adapt to the high clean environment, cross-area and cross-floor work, helping unmanned loading and unloading, handling automation, packaging automation and intelligent warehousing and logistics.

In the back-end process: mainly used in packaging, chemical composition, testing and sorting, module assembly, PACK assembly and finished products into the warehouse and other links. Mobile robots can play a different process between the transfer and connection, so that each process can be more orderly and efficient flow. In the back-end process of lithium battery production, unmanned forklift and backpack AGV/AMR are more widely used.

The seamless connection between each process through AGV/AMR robots can realize data cascade and improve the degree of factory intelligence and automation; the application of robots can also reduce the material damage in the handling process, improve the accuracy of transportation, and better meet the peak demand of full production of the whole line.

Advantages:

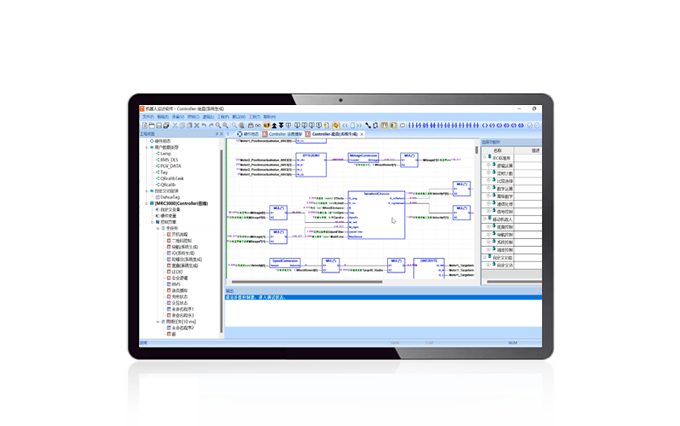

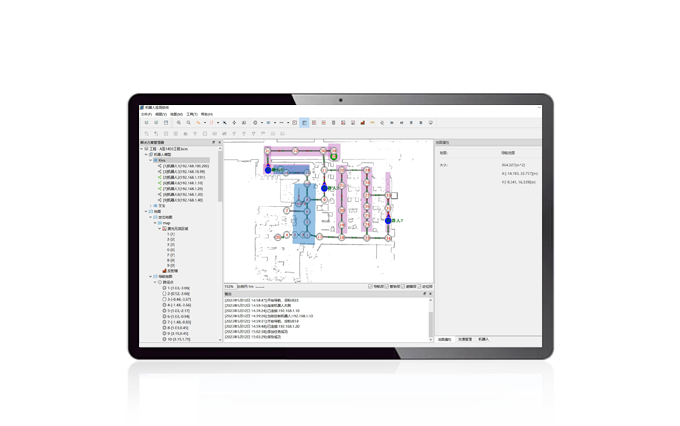

1.Do not need to rebuild the site, can be quickly built through the tool software, complete the path planning

2.It can realize cross-region and cross-floor work, solving cross-region and cross-floor handling problems.

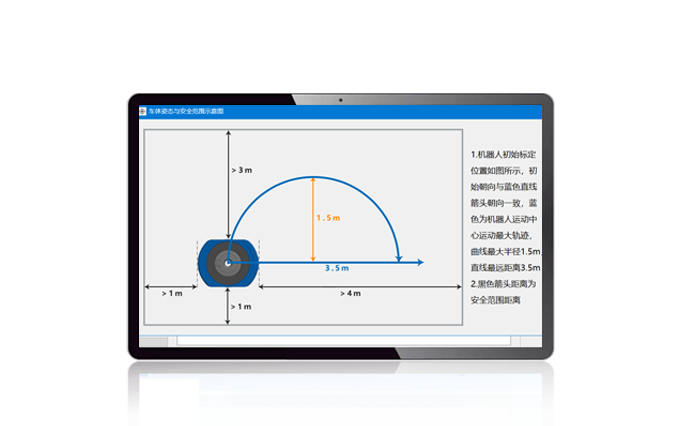

3.It can complete the accurate docking of equipment, material transfer, and adapt to the complex dynamic environment.

4.It can cope with the test of high clean and high temperature environment, can be 7 * 24 hours uninterrupted work.

Mobile robots in the lithium industry has a wide range of application prospects, can improve production efficiency, reduce costs, and improve product quality. With the continuous development and improvement of technology, mobile robots will play an increasingly important role in the lithium industry. The booming development of the lithium battery industry is the result of global energy constraints, scientific and technological progress, policy support and expanding market demand.